Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

Composite: An interesting material

However, composite is also interesting for mass production because it is light, durable and extremely strong, and can therefore make a substantial contribution to, among other things, reducing CO2 emissions from vehicles (lighter is less fuel / energy) and improving the lifespan of products (less waste and maintenance).

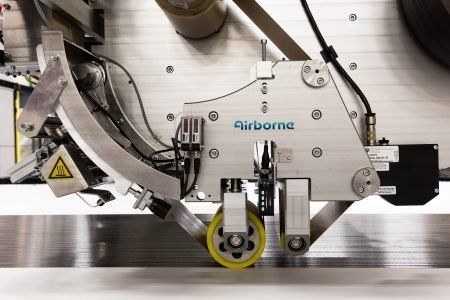

A complicated production process

Making composite products is also complicated however. There is a lot of freedom of choice in the materials and how a composite laminate can be built. Moreover, automation also requires a lot of machine settings that determine the right quality of the product. This is complex and as a result, the adoption of composite is slow. In order to accelerate it, Airborne and VIKTOR have built an online portal. The portal allows you to quickly and efficiently design products, without requiring in-depth knowledge of composite.

Personalized design for customers

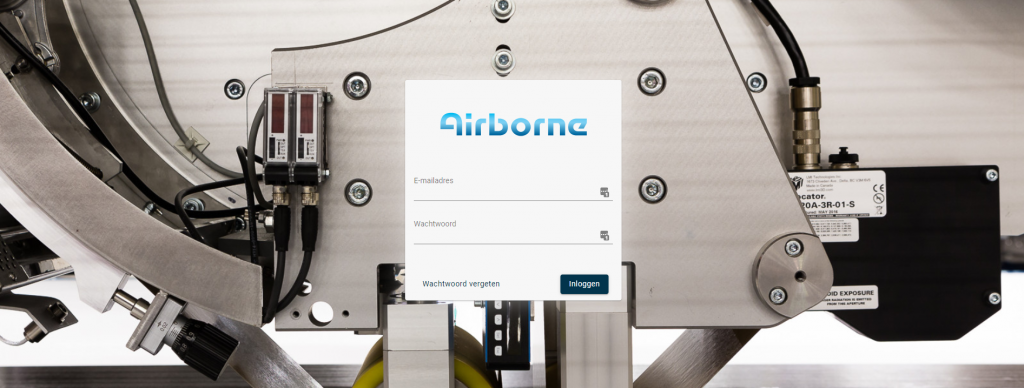

Now, customers can design their laminate online themselves in the On-Demand Manufacturing Portal created on the VIKTOR platform. Here customers can configure their own product. Among other things, they can determine the dimensions, the type of material, the number of layers and the orientation. Based on the design, the price and other relevant data are automatically calculated. This allows the customer to search for what suits them and whether their design meets the requirements. If the customer is satisfied with the design, they can order it online right away. The design is converted into a production file and immediately forwarded to a production robot in the Airborne factory.

“By means of the On-Demand Manufacturing Portal we can let our customers order composite laminates fully automatically online. This allows the customer to independently design a high-quality laminate, including multiple design iterations, saving time for everyone.” - Sarah de Smet, projectmanager at Airborne

The role of the VIKTOR application

VIKTOR determines the cheapest way to make the product. The application takes production times and material loss into account. The instructions for the production robots are automatically generated and sent to the different robots, which can then directly make the product.

Want to know more? Try it yourself!

On the Airborne website you can read more about the portal and find the url to register and make your own laminate. Give it a try!