Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

Airborne: Affordable and easy-to-use composits

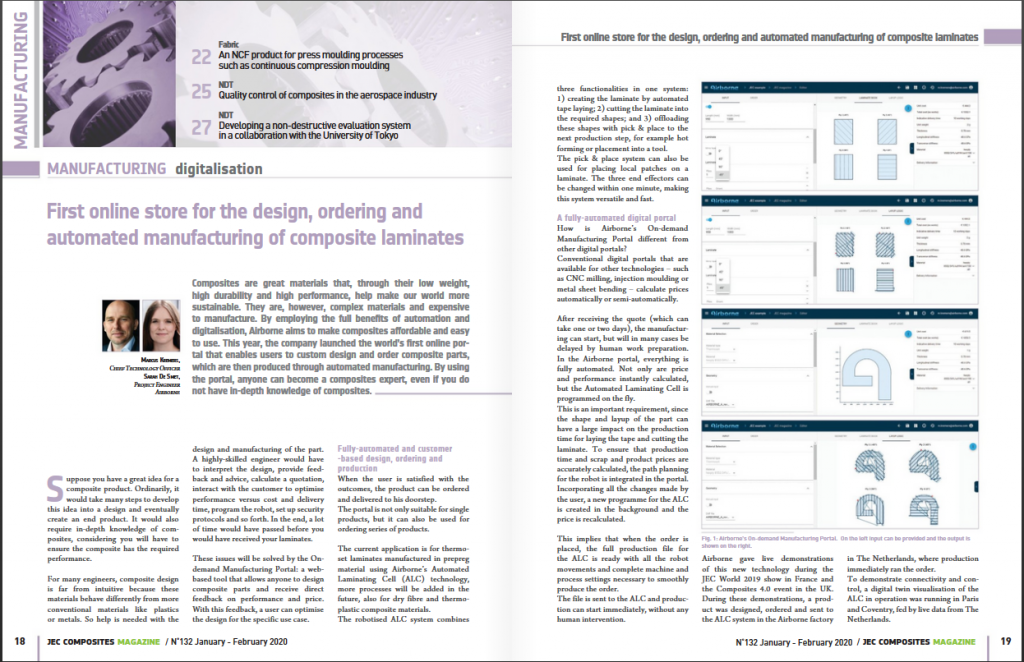

By employing the full benefits of automation and digitalisation, Airborne aims to make composites affordable and easy to use. This year, the company launched the world’s first online portal that enables users to custom design and order composites parts, which are then produced through automated manufacturing. By using the portal, anyone can become a composites expert, even if you do not have in-depth knowledge of composites.

A difficult material

Suppose you have a great idea for a composite product. Ordinarily, it would take many steps to develop this idea into a design and eventually create an end product. It would also require in-depth knowledge of composites, considering you will have to ensure the composite has the required performance.

For many engineers, composite design is far from intuitive because these materials behave differently from more conventional materials like plastics of metals. Sol help is needed with the design and manufacturing of the part. A highly-skilled engineer would have to interpret the designs, provide feedback and advice, calculate a quotation, interact with the customer to optimise performance versus cost and delivery time, program the robot, set up security protocols and so forth. In the end, a lot of time would have passed before you would have received your laminates.

The first online composit store

These issues will be solved by the On-demand Manufacturing Portal: a web-based tool that allows anyone to design composite parts and receive direct feedback on performance and price. With this feedback, a user can optimise the design for the specific use case.

Fully-automated and customer-based design, ordering and production

When the user is satisfied with the outcomes, the product can be ordered and delivered to his doorstep. The portal is not only suitable for single products, but it can also be used for ordering series of products.

More is coming...

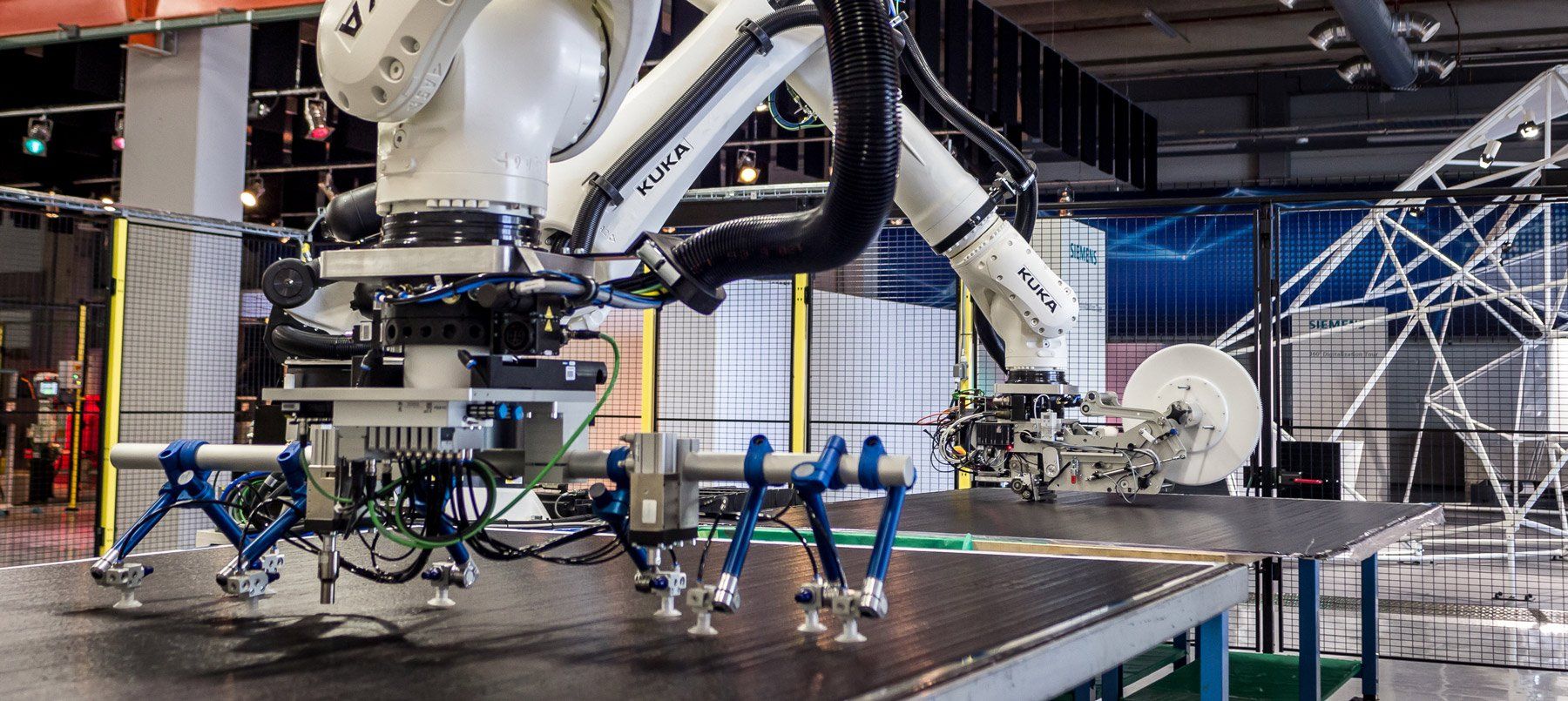

The current application is for thermo-set laminates manufactured in prepreg material using Airborne’s Automated Laminating Cell (ALC) technology, more processes will be added in the future, also for dry fibre and thermo-plastic composite materials. The robotised ALC system combines three functionalities in one system: 1) creating the laminate by automated tape laying; 2) cutting the laminate into the required shapes; and 3) offloading these shapes with pick & place to the next production step, for example hot forming or placement into a tool. The pick & place system can also be used for placing local patches on a laminate. The three end effectors can be changed within one minute, making this system versatile and fast.

Why Airborne?

A fully-automated digital portal

How is Airborne’s On-demand Manufacturing Portal different from other digital portals?

Conventional digital portals that are available for other technologies – such as CNC milling, injection moulding or metal sheet bending – calculate prices automatically or semi-automatically.

After receiving the quote (which can take one or two days), the manufacturing can start, but will in many cases be delayed by human work preparation. In the Airborne portal, everything is fully automated. Not only are price and performance instantly calculated, but the Automated Laminating Cell is programmed on the fly. This is an important requirement, since the shape and layup of the part can have a large impact on the production time for laying the tape and cutting the laminate. To ensure that production time and scrap and product prices are accurately calculated, the path planning for the robot is integrated in the portal. Incorporating all the changes made by the user, a new programme for the ALC is created in the background and the price is recalculated.

Smooth and quick order production

This implies that when the order is placed, the full production file for the ALC is ready with all the robot movements and complete machine and process settings necessary to smoothly produce the order. The file is sent to the ALC and production can start immediately, without any human intervention.

Airborne gave live demonstrations of this new technology during the JEC World 2019 show in France and the Composites 4.0 event in the UK. During these demonstrations, a product was designed, ordered and sent to the ALC system in the Airborne factory in The Netherlands, where production immediately ran the order.

To demonstrate connectivity and control, a digital twin visualisation of the ALC in operation was running in Paris and Coventry, fed by live data from The Netherlands.

2020 / JEC COMPOSITES MAGAZINE