Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

Saving thousands of hours with automation

VINCI Construction, a global leader in the construction industry, has empowered its engineers to build professional web applications for engineering automation and distributes them worldwide using VIKTOR.

One application developed by VINCI automates the design of crane foundations, including reporting and construction drawings. This innovation has dramatically reduced the time to design a crane foundation from 3-5 days to just 15 minutes, saving thousands of engineering hours annually.

"Using VIKTOR, we developed an application that automates the design process for crane foundations. This innovation not only saves thousands of engineering hours per year but also provides us with the flexibility to quickly generate new solutions when project requirements change.”

Alexandre Cousin

Head of Generative Design | VINCI Construction

About VINCI Construction

VINCI Group, one of the world's top 10 largest construction firms, boasts an unparalleled range of construction-related expertise. With a presence in over 100 countries, the group comprises more than 1,300 companies and employs 119,000 people worldwide.

Crane Foundations: A Multidisciplinary Challenge

"Designing a foundation typically takes between 3 and 5 days of work. In practice, however, the process often takes much longer as different specialists depend on each other's input and availability," explains Alexandre Cousin, Head of Generative Design at VINCI Construction.

The process involves several steps:

- Project planners determine the crane requirements, such as its height, reach, and maximum load capacity.

- The structural engineer uses input from the project planner and geotechnical engineer to design the foundation.

- Finally, a designer creates the production drawings.

"The reality in our industry is that things always change," Alexandre adds. "Sometimes we need to redesign the foundation due to last-minute changes in project requirements or soil conditions. In these situations, it's especially important that we can react quickly to avoid delays."

"Given the number of crane foundations we design and the time it takes, we saw a tremendous opportunity for automation. Besides saving time, automation would give us the agility to react quickly to project changes without delays.”

Alexandre Cousin

Head of Generative Design | VINCI Construction

Searching for software integration

When Alexandre's team at VINCI Construction set out to automate crane foundation design calculations, they faced a significant challenge: each specialist used different software packages. Automating the process meant connecting Autodesk Robot Structural Analysis, Grasshopper/Rhino, Excel, and Python scripts.

In their search for a solution, they discovered VIKTOR. This platform provided the perfect means to connect everything seamlessly, requiring only basic Python skills.

"VIKTOR is the only product that empowers our own engineers to create user-friendly applications and seamlessly integrate all our software packages. With VIKTOR, we have the flexibility to develop anything we need.”

Alexandre Cousin

Head of Generative Design | VINCI Construction

Total design automation

Alexandre states, "Our goal was to calculate crane foundation designs in 15 minutes, whereas this would normally take anywhere from 3 to 5 days."

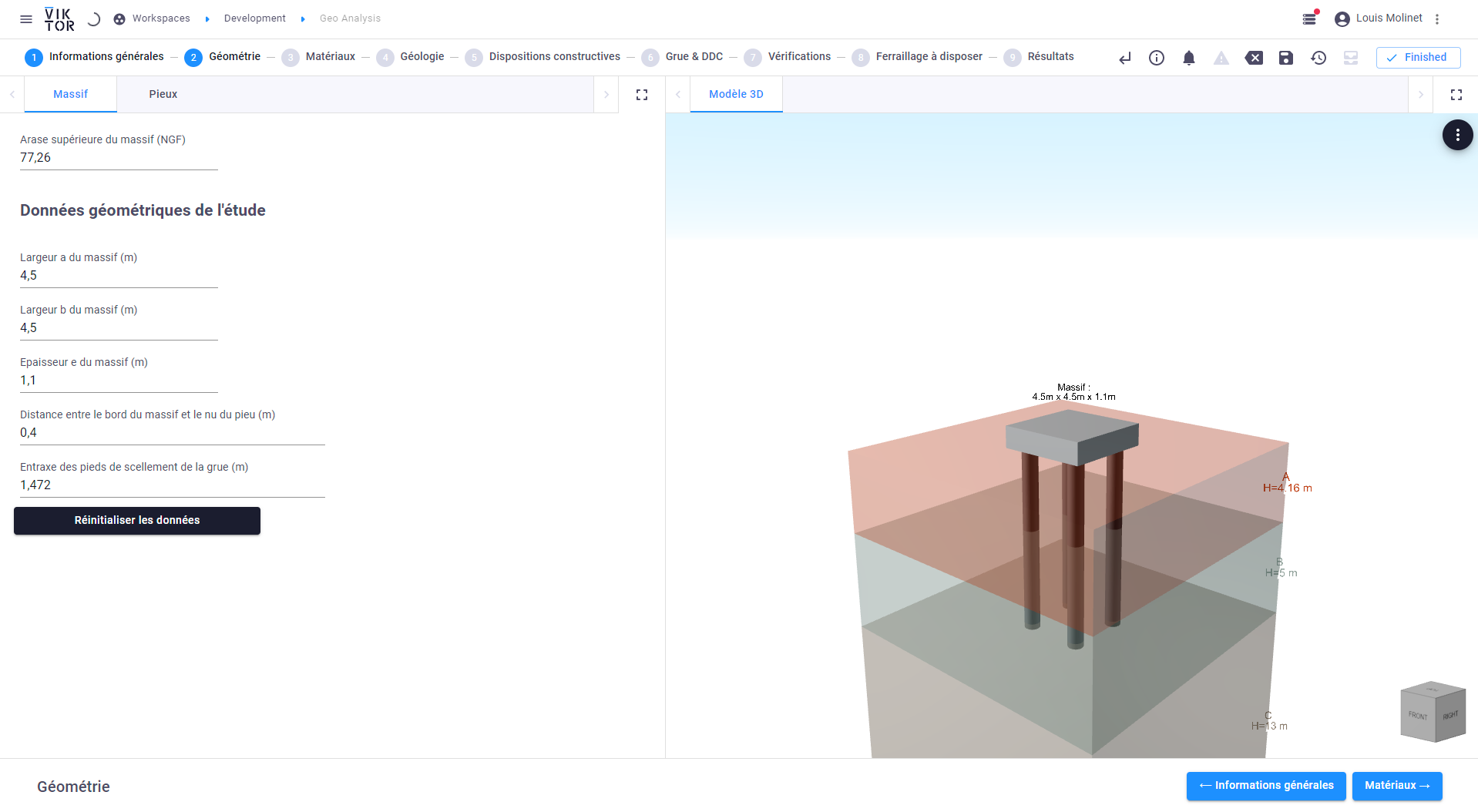

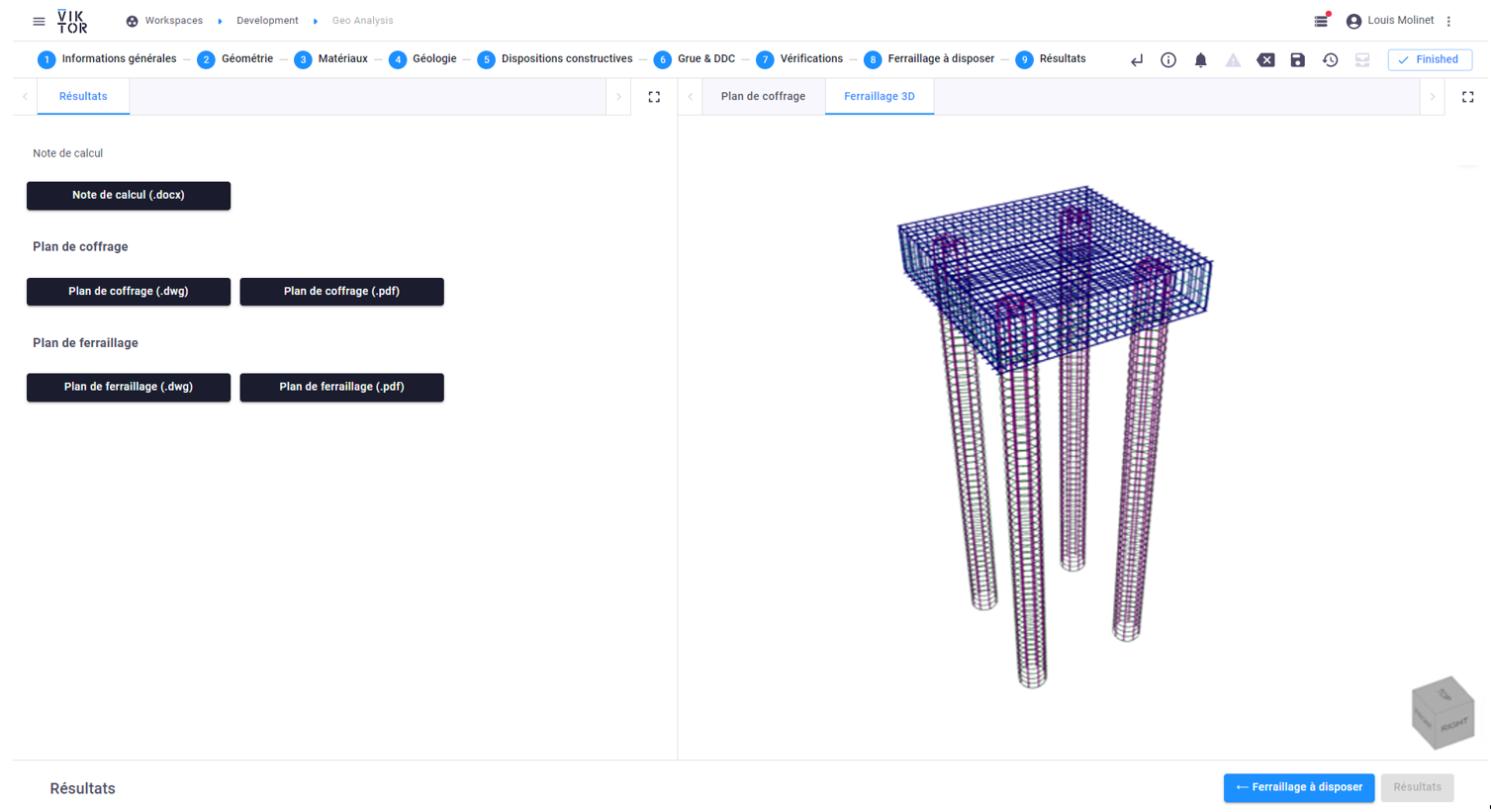

After just a few weeks, VINCI's team had achieved that ambitious goal. Alexandre explains, "The application truly automates the complete process. It performs geotechnical checks, structural calculations, determines the amount of reinforcement, creates 3D models, production drawings, and all required reports."

He adds, "Additionally, it runs optimizations and checks many design variations until finding the best solution, all in a fraction of the time it took before."

3D view of a crane foundation geometry in VIKTOR

3D view of a crane foundation geometry in VIKTOR

3D view of final crane foundation reinforcement design in VIKTOR

3D view of final crane foundation reinforcement design in VIKTOR

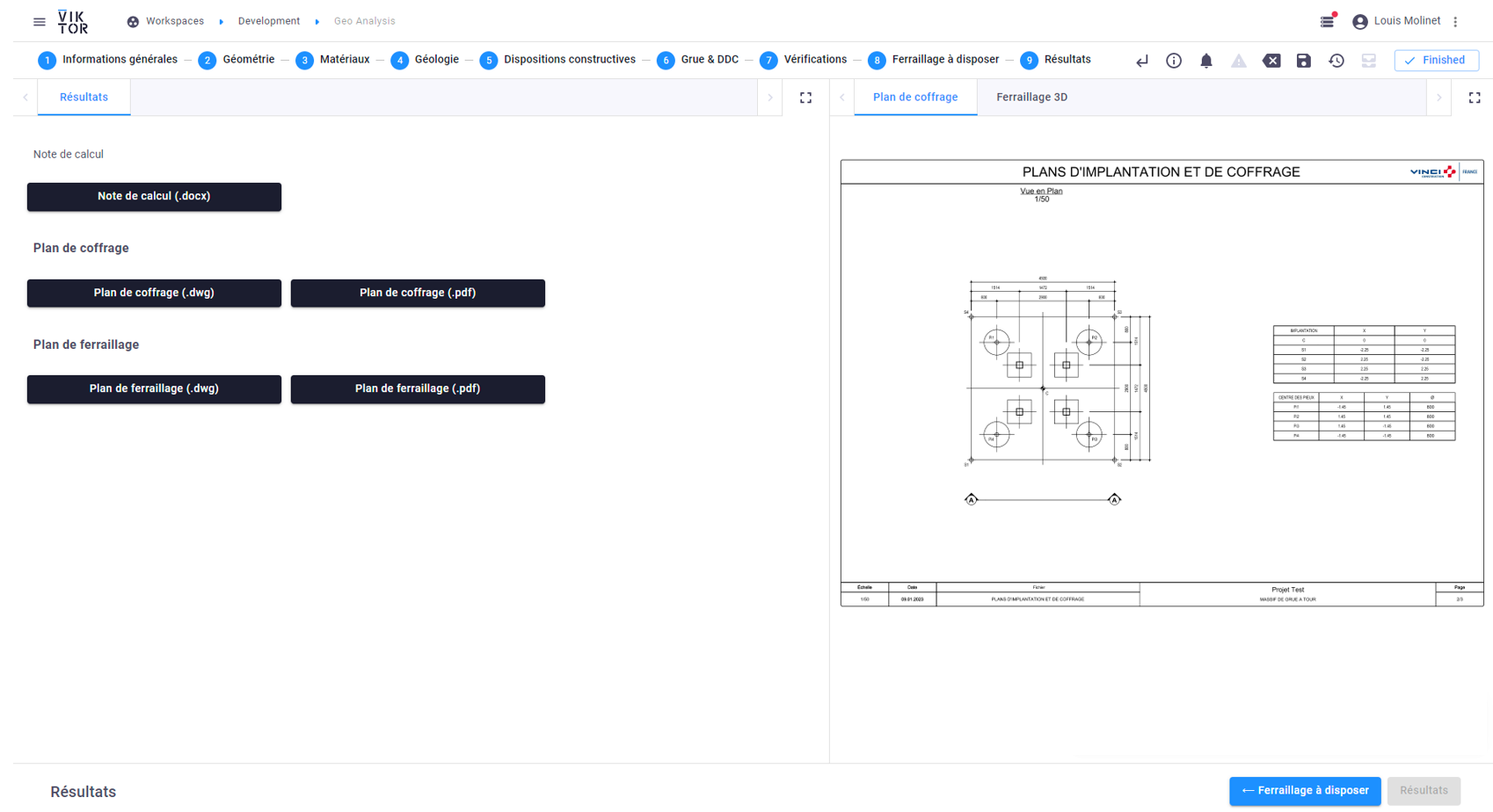

And the accompanying formwork plan

And the accompanying formwork plan

Large-scale engineering efficiency

VINCI's engineers design up to 225 crane foundations annually, and the application covers about 70% of these cases. The app features an intuitive user interface that anyone in VINCI can use, including colleagues without programming experience. Moreover, it doesn't require users to have any software packages installed on their laptops.

The goal is for all VINCI teams in France to adopt the application, freeing up time for more technical challenges. Alexandre adds, "Although essential, crane foundations are not the most exciting part of an engineer's job. Automation applications like this give our engineers more time for complex and rewarding problems, where we provide the most value for our customers."

"By automating the design of 100 crane foundations per year, we save approximately 300 engineering days annually. The impact on our efficiency and productivity is immense!”

Alexandre Cousin

Head of Generative Design | VINCI Construction