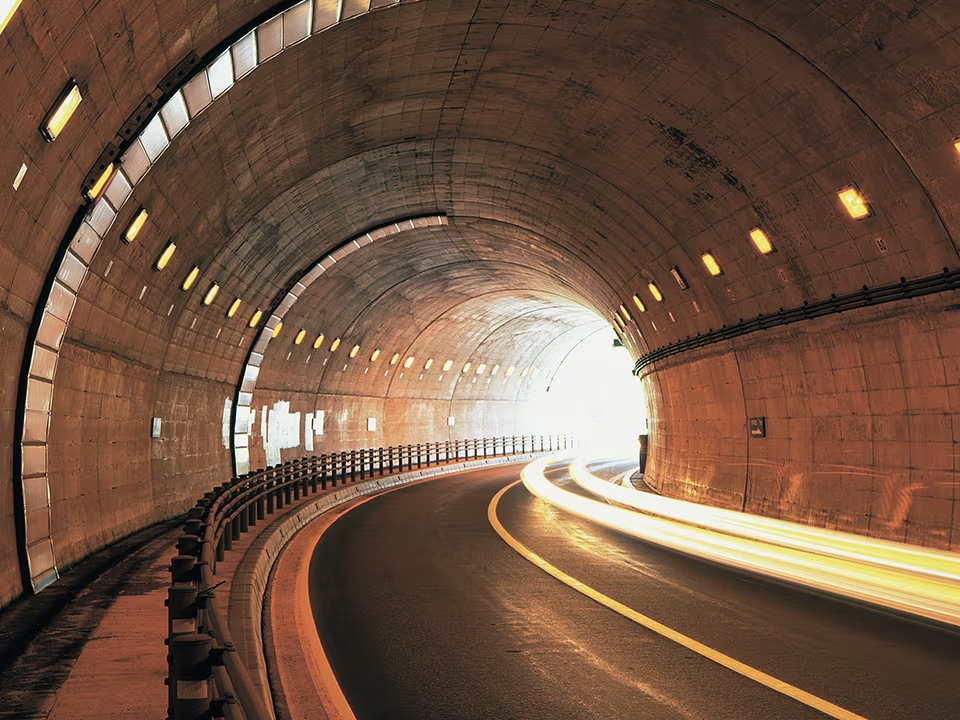

The Fehmarnbelt tunnel

Spanning 18 kilometres, the Fehmarnbelt tunnel will feature a four-lane motorway and two electrified railway lines. By drastically cutting travel time from over an hour by ferry to just 10 minutes by car and 7 minutes by train, this development not only enhances connectivity but also significantly reduces traffic emissions. This is achieved by shifting freight transportation from road to rail, minimizing the need for trucks to cross Storebælt, Denmark, ultimately contributing to a decrease in overall CO2 emissions.

Challenges of complex tunnel design

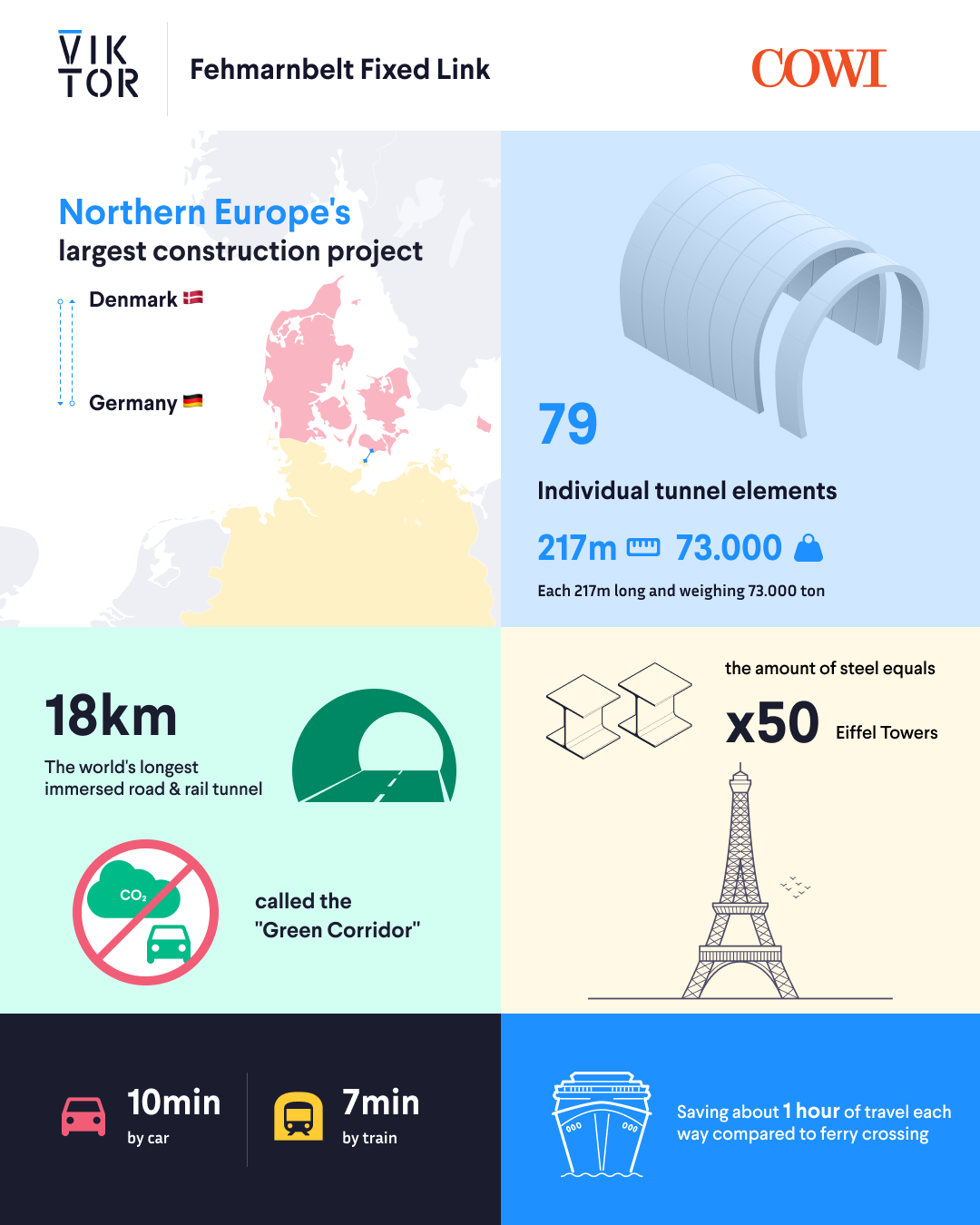

In cooperation with COWI a parametric design application is developed to optimise the design of the tunnel.

COWI faced the challenge of managing the complexity of the tunnel’s 79 elements, each measuring 217 meters long and subject to varying loads and soil conditions. This variability necessitated tailored steel reinforcement for each element, making the design process labor-intensive and time-consuming.

The solution

To address this challenge, the parametric design application, developed on the VIKTOR platform, assists geotechnical and structural engineers in automating the search for optimal design solutions.

The app integrates with Autodesk Robot and operates 24/7, performing extensive calculations—including load cases, load combinations, concrete crack analysis, and post-processing—on large batches of data. This automation not only speeds up the design process but also ensures the most efficient use of materials, with the total amount of steel used in the tunnel equivalent to about 50 Eiffel Towers and each element weighing 73,000 tonnes.

Why VIKTOR?

The following clip features an interview with a COWI engineer who contributed to the Fehmarnbelt project and the development of its corresponding VIKTOR application.

In the recording, Senior Bridge Specliasist Thomas W. Jensen shares insights into the project, explains why VIKTOR was chosen to develop the application and reflects on his experience creating an app with VIKTOR.

"The VIKTOR application is easy to access and ensures everyone works with the most up-to-date data. Before using VIKTOR, only a few people could manage the data, which caused bottlenecks. Now, colleagues can process it themselves with ease. In a short time, we built a powerful app to handle all our data, freeing up time for optimizations and enabling us to use fewer materials."

Thomas W. Jensen

Former Senior Bridge Specialist at COWI

Loading...