Download the white paper and get INSPIRED

Learn how collaborative parametric design models allow you to work together for better solutions.

Taking control over the full process

Before this application, Heijmans outsourced the design of wind turbine foundations. Now, with extensive research and the ability to store this knowledge directly in the application, they deliver complete designs themselves. This shift gives them greater control over the entire process.

“Previously, we relied on third parties for wind turbine foundation designs,” Tom notes. “Now, we have all the knowledge in-house, allowing us to communicate faster and avoid rising costs from external consultations. This tool lets us deliver designs much more quickly and efficiently.”

With full control over the process, Heijmans expects to lower costs and improve success rates in tenders.

Multidisciplinary automation

Heijmans has a history of developing applications to automate and optimize processes for individual departments. However, the Wind Turbine Foundation tool marks a significant shift.

"This project was unlike anything we’d done before," explains Tom Nillesen, Lead Developer of Parametric Design at Heijmans Construction and Geotechnics. "It was our first application that integrated multiple disciplines, making it not only more complex but also much larger."

Heijmans leveraged previously developed logic from earlier applications to build the Wind Turbine tool, which was critical in speeding up the development process. "Reusing code means we don’t have to start from scratch every time," Tom explains. "It saves us time and effort, as we can pull from our Python code library whenever needed."

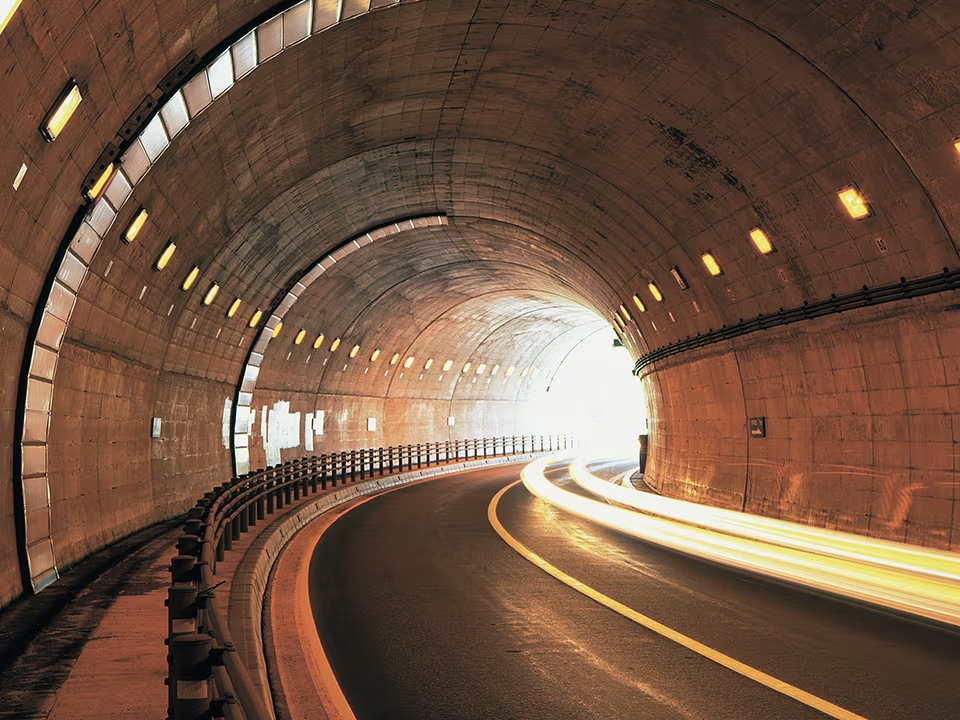

The Wind Turbine application was Heijmans' first tool designed for use across multiple departments. Wind turbine foundation design requires data from a variety of sources, so Heijmans incorporated input from three departments: Wind Energy, Construction and Geotechnics, and Calculations. The process is complex, starting with the Wind Energy department receiving a tender request. From there, Construction and Geotechnics develops the tender design, which Calculations uses to determine the cost estimate. Once the design is approved, Heijmans oversees the realization of the wind turbine foundation.

How the application works

Built on the cloud-based VIKTOR platform, the Wind Turbine tool integrates various calculation software packages, including IDEA StatiCa, SCIA Engineer, and D-Foundations. It handles data from multiple sources, such as soil research, turbine suppliers, and pile types. Here's how the process unfolds:

-

Input Data: Information about soil capacity, turbine specifications, and pile types is uploaded and stored within the application. Soil research data is automatically classified, while turbine and pile databases are created for easy access.

-

Creating a Tender Design: After all data is uploaded, users can define input parameters like foundation plate size and pile numbers. The tool runs geotechnical calculations via D-Foundations and structural analysis with SCIA Engineer. If the design meets the criteria, a reinforcement design is generated using IDEA StatiCa. Otherwise, adjustments are made, and calculations are re-run.

-

Cost Calculation: After completing the calculations, the tool provides specific information to determine the cost of the project.

Since the Wind Turbine application is multidisciplinary, it allows all relevant departments to access the necessary information. However, to maintain structure, only designers responsible for calculations actively operate the tool, providing key information to other departments as needed.

Towards a unified system

The Wind Turbine application was built with collaboration between three departments in mind, but Heijmans has aspirations to create an “umbrella application” that integrates even more departments, such as Soil and Roads, into one seamless workflow.

“Our goal is to build a network of applications across the organization, where any change automatically updates related processes. We’ve started small, but with success from projects like the Wind Turbine tool, we’ll continue expanding,” says Tom.

Discover how you can develop your own parametric design tools!